Gear Coupling

What is a Gear Coupling?

A Gear Coupling is a Mechanical Device to Transmit Heavy Torque from one shaft to another . It Consist of Two Hubs with Gear on Outer diameter and two flanges with internal Teeth.

We have developed Gear coupling with Triple Crowned Gears on all working portions of the teeth, so that they can slide freely to accommodate misalignment and movement. As a result connected equipment is protected from damaging loads.

Longer Life

These Gear couplings is manufactured as per international Standard so a longer working life is virtually built into these coupling.

Higher Misalignment Capability

These Gear Coupling is Equipped with Triple Crowned Gears that allow higher misalignment accommodating capability.

DEL JAYESS GEAR COUPLING ARE BEING USED BY ALL INDUSTRIES LOCATED IN DELHI, GURGAON, SONEPAT, PANIPAT, CHANDIGARH, PALWAL, GHAZIABAD, NOIDA, ALWAR , PUNE, BOMBAY,RAJASTHAN, JAIPUR, RUDRAPUR, UTTRAKHAND AND ALL INDIA, USA, UK, GERMANY.

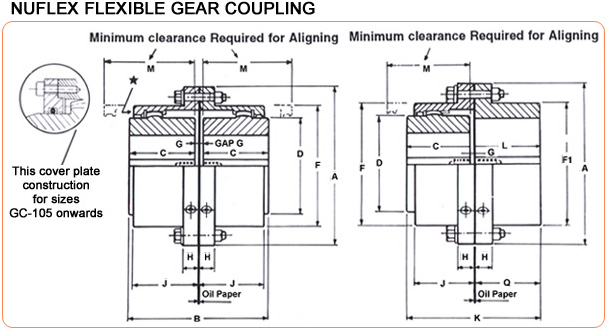

| GC MODEL | HP CAPACITY AT 100 RPM | MAX TORQUE Kg.M | MAX R.P.M | BORE MIN | A | C | D | F | M | G | H | BORE MAX | J | B | WR KGM | WT. IN KG. | K | Q | BORE MAX | F1 | WR2 KGM2 | WT IN KG. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GC 100 | 7 | 50 | 8000 | 10 | 120 | 45 | 50 | 75 | 55 | 1.5 | 15 | 32 | 40 | 93 | 0.03 | 4.5 | 93 | 46.5 | 45 | 70 | 0.04 | 5 |

| GC 101 | 14 | 100 | 6300 | 20 | 170 | 55 | 65 | 110 | 65 | 2.5 | 17 | 45 | 49 | 115 | 0.14 | 11 | 115 | 57.5 | 60 | 85 | 0.15 | 11 |

| GC 102 | 35 | 250 | 5000 | 30 | 185 | 70 | 85 | 125 | 80 | 2.5 | 17 | 60 | 62 | 145 | 0.2 | 15 | 145 | 72.5 | 75 | 110 | 0.24 | 15 |

| GC 103 | 63 | 450 | 4000 | 40 | 220 | 85 | 105 | 150 | 105 | 2.5 | 20 | 75 | 78 | 175 | 0.48 | 25 | 175 | 87.5 | 90 | 130 | 0.51 | 20 |

| GC 104 | 119 | 850 | 3350 | 50 | 250 | 105 | 130 | 175 | 125 | 2.5 | 20 | 90 | 96 | 215 | 0.95 | 39 | 215 | 107.5 | 110 | 160 | 1 | 40 |

| GC 105 | 182 | 1300 | 2800 | 60 | 290 | 110 | 155 | 200 | 140 | 5 | 25 | 110 | 106 | 230 | 1.9 | 57 | 230 | 115 | 130 | 185 | 2 | 60 |

| GC 106 | 280 | 2000 | 2500 | 75 | 320 | 125 | 175 | 230 | 155 | 5 | 25 | 125 | 117 | 260 | 3 | 85 | 260 | 130 | 150 | 215 | 3.3 | 80 |

| GC 107 | 490 | 3500 | 2100 | 90 | 350 | 140 | 205 | 260 | 175 | 5 | 25 | 140 | 134 | 290 | 5.25 | 103 | 290 | 145 | 170 | 240 | 5.8 | 106 |

| GC 108 | 630 | 4500 | 1900 | 105 | 380 | 155 | 230 | 290 | 190 | 5 | 25 | 160 | 147 | 320 | 8.5 | 138 | 320 | 160 | 200 | 285 | 9.5 | 149 |

| GC 109 | 74 | 5600 | 1700 | 125 | 430 | 165 | 250 | 330 | 205 | 5 | 27 | 180 | 157 | 340 | 15 | 210 | 340 | 170 | 220 | 315 | 16.8 | 170 |

| GC 110 | 1148 | 8200 | 1400 | 140 | 490 | 180 | 310 | 390 | 220 | 5 | 27 | 220 | 171 | 370 | 30.5 | 277 | 370 | 185 | 260 | 370 | 35 | 264 |

| GC 111 | 1536 | 11000 | 1250 | 160 | 545 | 200 | 350 | 445 | 240 | 5 | 30 | 260 | 192 | 410 | 58 | 550 | ||||||

| GC 112 | 2053 | 14700 | 1120 | 180 | 590 | 240 | 400 | 490 | 280 | 5 | 30 | 300 | 231 | 490 | 88 | 710 | ||||||

| GC 113 | 2793 | 20000 | 1000 | 200 | 680 | 260 | 440 | 555 | 310 | 7.5 | 35 | 330 | 242 | 535 | 138 | 980 | ||||||

| GC 114 | 3994 | 28600 | 900 | 220 | 730 | 280 | 500 | 610 | 230 | 10.5 | 35 | 370 | 266 | 575 | 291 | 1320 |